Technical Parameters:

| Item/Model | unit | X6330 | X6330A | ||

| Workbench area | millimetre | 305×1370(12”x54”)/305×1500(12”x58”) | |||

| Table transverse travel | millimetre | 870 1000 | |||

| Longitudinal travel of the table | millimetre | 380 | |||

| Vertical travel of the table | millimetre | 400 | |||

| Number and size of T-slots | millimetre | 3×16 | |||

| Telescopic arm travel | millimetre | 500 | |||

| The distance from the spindle end to the work surface | millimetre | 0~350 | |||

| Spindle bore taper | – | Standard: ISO40 | |||

| Spindle travel | millimetre | 127 | |||

| Spindle speed | rotate speed | Standard: 16-speed (Shiftgrade) 50HZ: 66-4540 60HZ: 80-5440 | |||

| rotate speed | Special option: stepless variable speed 60-3600 | ||||

| Spindle feed | millimetre | Three gears: 0.04 (0.0015")/0.08 (0.003")/0.15 (0.006") mm/rev | |||

| Spindle motor power | kW/hp | 3.75KW/5HP | |||

| The milling head rotates left and right | ° | 90° | |||

| The milling head rotates back and forth | ° | 45° | Fixed FIX | ||

| Package size | Single-unit packaging | millimetre | 1566x1650x2080 | ||

| Two sets of packing | millimetre | 1720x1800x2175 | |||

| Gross weight/unit | kg | 1430 | 1650 | ||

The turret milling machine is also known as the rocker universal milling machine

Product Description:

Milling machines are tools used by engineers and machine creators to cut metal into specific shapes. A turret mill is a vertical milling machine, which means that the spindle (the area where the cutting is performed) is placed vertically. The turret milling machine is considered a versatile unit as it can create a variety of shapes. It has a spindle that can be raised or lowered to create different cutting depths. Turret milling machines are only effective if they maintain a relatively small size, as the sleeve is difficult to operate with larger units.

Features:

The machine tool has good rigidity and can withstand heavy load cutting;

The spindle motor of the machine tool has high power and a wide range of speed regulation, which can give full play to the tool efficiency and can carry out high-speed cutting.

The wear-resistant castings of the machine tool are made of vanadium titanium wear-resistant cast iron, and the important transmission parts are made of high-quality alloy steel;

Ensure the durability and stability of the machine;

The machine has a complete lubrication system.

Standard equipment

| pull rod | Handle lubrication | Electrical cabinets |

| Tools & Toolboxes | Work lights | 16-speed milling head |

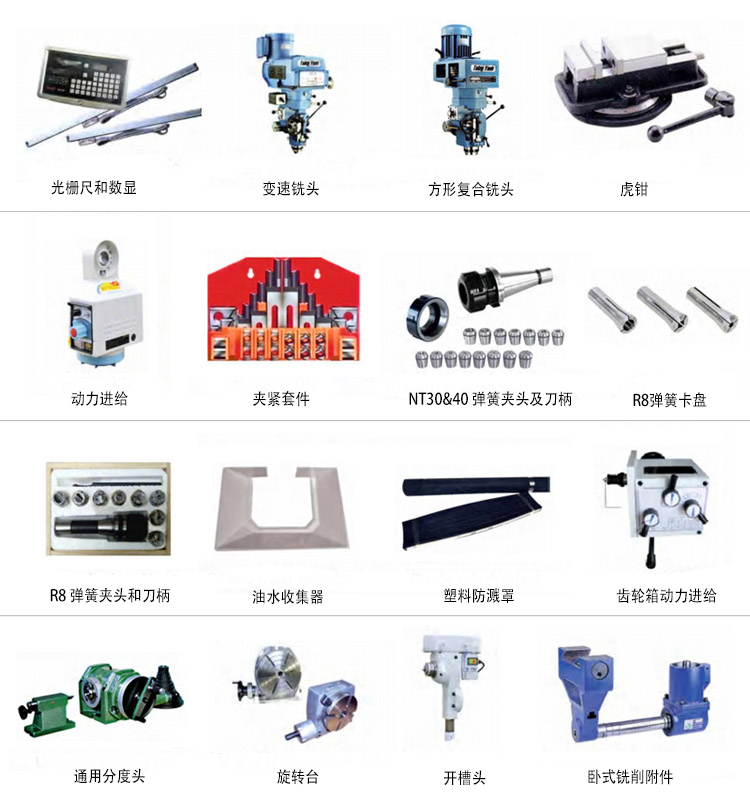

Optional equipment

必须是数字

不能为空

E-mail格式不对

手机号格式不对

不能为空

不能为空