Technical Parameters:

| Model parameters | HC500A | HC630A | HC800A |

| Table size (mm) | 500×600 | 630×630 | 800×800 |

| Table maximum load (kg) | 500 | 1500 | 3000 |

| Table T-groove (number of grooves x wide groove x groove spacing) (mm) | 6x 14x 80 | 5x18x125 | 5x22x160 |

| X/Y/Z Stroke (mm) | 800/600/600 | 1000/800/900 | 1200/900/900 |

| Rapid traverse speed (X /Y /Z) m/min | 15/12/15 | 15/12/15 | 15/12/15 |

| XYZ cutting speed(mm/min) | 1 ~ 5000 | 1~5000 | 1 ~ 5000 |

| Spindle centerline to table (mm) | 50~650 | 0~800 | 0~900 |

| Spindle face to table center (mm) | 150~750 | 200~1100 | 200~1100 |

| Spindle speed (rpm) | 6000 | 6000 | 6000 |

| Spindle power (kW) | 11/15 | 15/18.5 | 18.5/22 |

| Spindle torque(Nm) | 143 | 249 | 307 |

| Shank form | BT50 | BT50 | BT50 |

| Pull studs | BT50-45° | BT50-45° | BT50-45° |

| Tool magazine capacity | 24 (manipulator) | 24 (manipulator) | 24 (manipulator) |

| Tool change time (seconds) | 3.5 (Knife to Knife) | 3.5 (Knife to Knife) | 3.5 (Knife to Knife) |

| Maximum tool weight (kg) | 25 | 25 | 25 |

| Max. tool diameter (mm) | Φ110 / Φ220 | Φ110 / Φ220 | Φ110 / Φ220 |

| Barometric pressure (MPa) | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Machine weight (kg) | 10500 | 12500 | 13500 |

| Machine profile dimensions (L x W x H) mm | 3800x 3000x 3020 | 4300x 3150x 3800 | 4300x 3150x 3900 |

Product features:

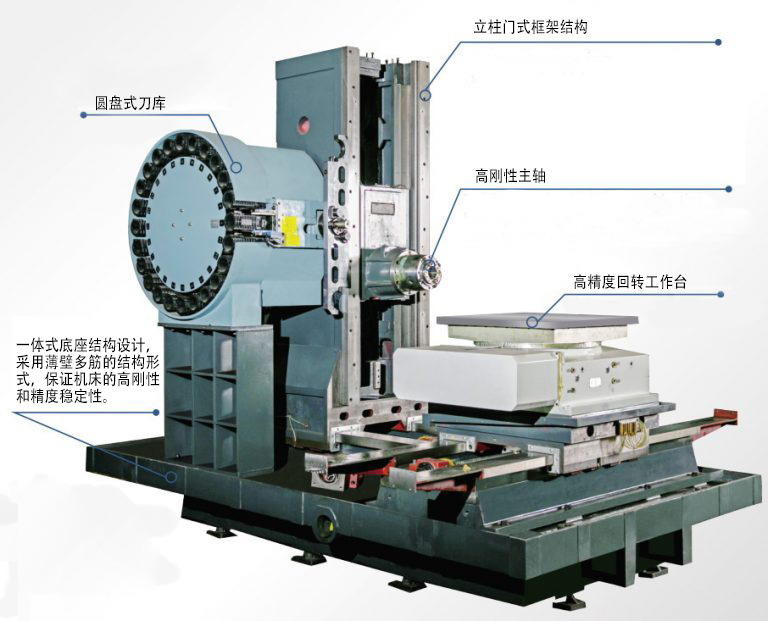

HC series The machine base, column, slide table and spindle box are all made of high-quality cast iron HT300.

The large foundation section adopts the design of dense reinforcement and adopts finite element analysis, which ensures high bending stiffness and torsional stiffness, makes it have a high natural frequency, and improves the vibration resistance.

The three-axis hard guide (quenched) meets the technical performance requirements. The amount of knives used is large, and the precision is high. After secondary aging treatment, the internal stress is eliminated. It has the characteristics of good overall rigidity, good vibration absorption and good seismic performance.

It is widely used in the processing of box parts, shell parts and disc parts in military, automobile, mold, machinery manufacturing and other industries. After the parts are clamped once, they can be processed in multiple processes such as milling, boring, drilling, expanding, reaming, tapping, etc., with high precision, high degree of automation, high reliability, high degree of mechatronics, simple operation, and beautiful overall appearance.

HC series horizontal machining center is a horizontal machining center designed and developed on the basis of absorbing advanced machine tool design concepts at home and abroad, the machine adopts a large-span guide rail design, the overall rigidity of the machine tool is good, the bearing capacity is strong, with CNC turntable, suitable for polyhedral processing such as car body parts, machine tool base, polygon, etc., a clamping can complete milling, boring, drilling, tapping and other rough and finishing processes.

The machine tool can choose FANUC and Siemens system, and the turntable, tool magazine, spindle, linear guideway, and lead screw are all Taiwanese brands.

| serial number | Standard configuration | serial number | Optional |

| 1 | 24 robot tool magazines | 1 | 32 robot chain tool magazines |

| 2 | Spindle air curtain dust prevention system | 2 | 40 robot chain tool magazines |

| 3 | Workpiece cooling system | 3 | Central outlet spindle (with high-pressure cooling) |

| 4 | Equal indexing CNC rotary table | 4 | ZF gearbox transmission |

| 5 | Automatic lubrication system | 5 | Spindle oil cooling |

| 6 | Spiral chip conveyor | 6 | Arbitrary indexing CNC rotary table |

| 7 | Chain type lifting chip conveyor | 7 | Scraper-type lifting chip conveyor |

| 8 | Integral protective shield | 8 | Three-axis encoder control |

| 9 | toolbox | 9 | Tool detection device |

| 10 | Anchor bolts and cushion blocks | 10 | Workpiece inspection device |

| 11 | Door Protector (Protective Door) | ||

| 12 | Hand-held crumb blowing air gun | ||

| 13 | Machine cleaning water gun | ||

| 14 | Simple oil-water separator |

必须是数字

不能为空

E-mail格式不对

手机号格式不对

不能为空

不能为空