Technical Parameters:

| project | unit | MC(K)W7520*25 | MC(K)W7520*35 | MC(K)W7525*40 | MC(K)W7525*50 | MC(K)W7530*60 | MC(K)W7535*60 | |

| Table size(W*L) | millimetre | 1600*2500 | 1600*3500 | 2000*4000 | 2000*5000 | 2500*6000 | 3000*6000 | |

| T-slot (size * distance * quantity) | millimetre | 28*200-7 | 28*200-7 | 36*250-7 | 36*250-7 | 28*200-7 | 36*250-7 | |

| Column spacing | millimetre | 2000 | 2000 | 2500 | 2500 | 2000 | 2500 | |

| Table speed | m/min | 5~25 | 5~25 | 5~25 | 5~25 | 5~25 | 5~25 | |

| X-axis maximum travel | millimetre | 2800 | 3800 | 4300 | 4300 | 3800 | 4300 | |

| Maximum grinding length | millimetre | 2500 | 3500 | 4000 | 4000 | 3500 | 4000 | |

| Y-axis travel | millimetre | 1800 | 1800 | 2300 | 2300 | 1800 | 2300 | |

| The distance from the center of the grinding head to the table | millimetre | 250-750 | 250-750 | 250-850 | 250-850 | 250-750 | 250-850 | |

| Maximum. Grinding weight | millimetre | 6000 | 6000 | 10000 | 10000 | 13000 | 15000 | |

| Table longitudinal speed | millimetre | 5~25 | 5~25 | 5~25 | 5~25 | 5~25 | 5~25 | |

| The grinding head moves laterally | Movement speed | m/min | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 |

| Minutes input unit | millimetre | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| The wheels move vertically | Z-axis max Stroke | mm/t | 500 | 500 | 600 | 600 | 600 | 600 |

| Movement speed | m/min | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | |

| Minutes input unit | millimetre | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| Grinding wheel head motor power | kw | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | |

| Wheel size (OD*Width*ID) | millimetre | 500*75*203 | 500*75*203 | 500*75*203 | 500*75*203 | 500*75*203 | 500*75*203 | |

| Spindle speed | kw | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | |

| Surface roughness | micron | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | |

| Total weight | kg | 21000 | 21000 | 30000 | 30000 | 56000 | 60000 | |

| Machine Size(L*W*H) | centimeter | 770*400*310 | 770*400*310 | 1100*440*320 | 1100*440*320 | 1500*500*360 | 1500*550*500 | |

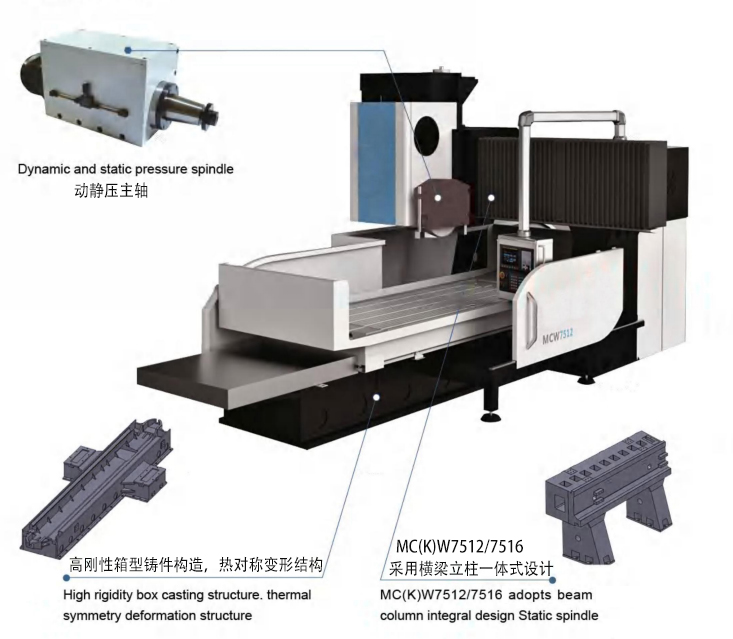

This series of machine tools adopts a gantry layout, and is composed of double columns, beams, and beds with a closed high-rigidity frame structure. It is a program-controlled (NC) fixed beam gantry rail grinder integrating mechanical, electrical, hydraulic grinding and other advanced technologies.

Product featuresHydrostatic

bearings have the advantages of high motion accuracy, no wear, long life, low starting power, high load capacity, and good vibration resistance at high speeds. Hydraulic longitudinal movement and variable speed The MKW series means that the machine can be configured with

a CNC

system extended to a 2-axis CNC machine.

UsesThis

machine is mainly suitable for grinding steel, cast iron and various non-ferrous metal parts particularly important surfaces, and can also grind non-metallic materials such as sapphire, and is suitable for grinding large and medium-sized parts in mechanical processing plants, abrasive processing factories and automobile and other industries.

Standard Accessories

Cooling System, Leveling Wedge, Foundation Screws, Wheel Flanges, Wheel Balance Mandrel, Standard Wheels, Operating Manual, Wheel Dressing Base, PLC Controller, and Touch Screen.

Optional accessories

diamond pen

magnetic separation cooling system

grinding wheel balance frame

DRO

electromagnetic chuck

必须是数字

不能为空

E-mail格式不对

手机号格式不对

不能为空

不能为空