| Model item |

Unit | SG2050NC2 | SG2550NC2 | SG3063NC2 | SG30100NC2 | SG4080NC2 | SG40100NC2 | |

| SG2050NC3 | SG2550NC3 | SG3063NC3 | SG30100NC3 | SG4080NC3 | SG40100NC3 | |||

| Table area (W×L) | mm | 200×460 | 254×508 | 305×635 | 305×1020 | 406×813 | 406×1020 | |

| The maximum amount of movement left and right | mm | 510 | 570 | 765 | 1130 | 910 | 1130 | |

| The maximum amount of movement in front and back of the table | mm | 238 | 275 | 340 | 340 | 450 | 450 | |

| The maximum distance from the spindle axis to the work surface | mm | 450 | 450 | 580 | 580 | 580 | 580 | |

| Magnetic chuck size | mm | 200×460 | 250×500 | 300×600 | 300×1000 | 400×800 | 400×1000 | |

| The workbench moves longitudinally | velocity | m/min | 5-25(NC2 model); 0.02-15(NC3 model) | |||||

| Electronic handwheel microfeed | mm/div. | 0.005(NC3 model) | ||||||

| The workbench moves laterally | Automatic feed | mm/stroke | 0.005~12 | |||||

| Maneuver speed | m/min | 0~1 | ||||||

| Electronic handwheel microfeed | mm/div. | 0.005 | ||||||

| The grinding head moves vertically | Automatic feed | mm/stroke | 0.001-0.05 | |||||

| Fast feed | m/min | 0~1 | ||||||

| Electronic handwheel microfeed | mm/diy | 0.001 | ||||||

| grinding wheel | rotate speed | rpm | 50Hz 2850 | 50Hz 1450 | ||||

| 60Hz 3450 | 60Hz 1750 | |||||||

| size | mm | 200×20×31.75 | 350×40×127 | |||||

| Spindle motor | kW | 1.5 | 2.2 | 5.5 | ||||

| Hydraulic station motor | kW | 0.75(NC2 model) | 2.2(NC2 model) | |||||

| Cooling pump motors | kW | 0.04 | 0.125 | |||||

| The parallelism of the workpiece machined towards the base surface | mm | 300:0.005 | ||||||

| Surface roughness of the workpiece | μm | Ras0.63 | ||||||

| Maximum load capacity of table (including suction cup) | kg | 120 | 180 | 270 | 400 | 500 | 600 | |

| Machine height | mm | 1675 | 1890 | |||||

| Floor area (L×W) | mm | 2050×1400 | 2300×1600 | 2900×2200 | 4400×2200 | 3600×2400 | 4400×2400 | |

| gross weight | kg | 1600 | 1800 | 2800 | 3500 | 3800 | 4300 | |

| Package dimensions (L×W×H) | mm | 1780×1500×2155 | 2000×2100×2150 | 2350×2220=2150 | 2950×2220×2150 | 2850×2270×2180 | 2950=2270×2150 | |

Product Description :

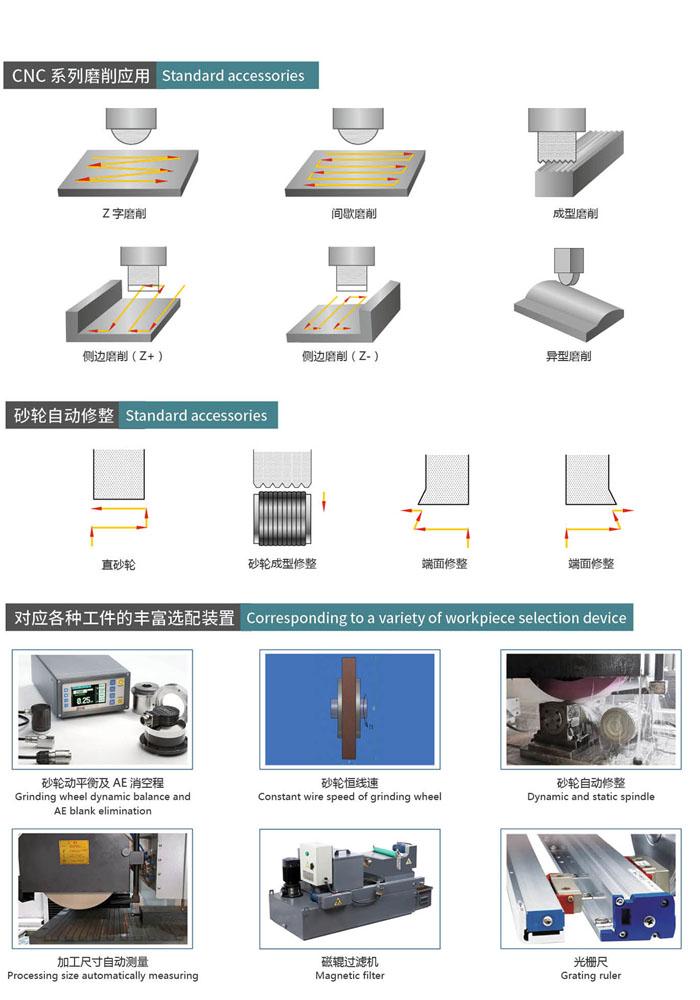

This series of machine tools is a two-axis or three-axis CNC surface grinder. Use SIMENS, FANUC or other CNC systems. It is widely used in precision mold manufacturing, precision optical parts, precision optical glass, medical equipment, mobile phone manufacturing and other precision parts processing; It is especially suitable for the processing of diamond, ceramic materials and cemented carbide materials. The machine can also use the grinding wheel face to grind the vertical plane of the workpiece. When grinding, depending on the shape and size of the workpiece, it can be attached to the magnetic chuck, fixed directly on the work surface, or clamped with other fixtures.

1. The basic parts such as the bed, saddle, column, grinding head body, and workbench are all made of high-strength cast iron, with stable organization and permanent quality guarantee.

2. The grinding head spindle adopts precision angular contact bearing, high rigidity spindle sleeve structure, high rotation accuracy, and easy use and maintenance.

3. NC2 series of hydraulic drive, up and down feeding, the front and rear axles adopt precision ball screws, AC servo motor and numerical control system control, high feed sensitivity, can realize plane, forming surface (two-axis linkage can realize different grinding wheel dressing, so as to achieve forming surface grinding), non-equidistant deep range wide groove or stepped automatic grinding, easy to operate, high efficiency.

4. NC3 series left and right feed, up and down feed, front and rear axes are controlled by precision ball screw, AC servo motor and CNC system, in addition to NC2 series functions, but also through the left and right, upper and lower shaft linkage to achieve convex and concave surface, arc surface and other special shape surface grinding.

必须是数字

不能为空

E-mail格式不对

手机号格式不对

不能为空

不能为空