Technical Parameters:

|

Model

parameter |

unit | HMC500APC | HMC630APC | HMC630SAPC | HMC800APC | |

| itinerary | Column travel stroke (X-axis) | millimetre | 800 | 1050 | 1050 | 1400 |

| Headstock travel (Y-axis) | millimetre | 750 | 900 | 750 | 950 | |

| Table travel (Z-axis) | millimetre | 850 | 1000 | 900 | 1370 | |

| The distance from the end face of the spindle to the center of the table | millimetre | 100-850 | 100-1000 | 130-1030 | 100-1050 | |

| The distance from the spindle center to the work surface | millimetre | 100-950 | 140-1160 | 0-750 | 150-1420 | |

| Feed | X-axis rapid traverse speed | mm/min | 48000 | 36000 | 20000 | 36000 |

| Y-axis rapid traverse speed | mm/min | 48000 | 36000 | 20000 | 36000 | |

| Z-axis rapid traverse speed | mm/min | 48000 | 36000 | 20000 | 36000 | |

| X/Y/Z axis cutting feed rate | mm/min | 20000 | 20000 | 10000 | 20000 | |

| workbench | Table size | millimetre | 500*500 | 630×630 | 630x 700 | 800×800 |

| Number of workbenches | 2 | 2 | 2 | 2 | ||

| Workbench indexing type | 。 | 1(0.001) | 1(0.001) | 1(0.001) | 1(0.001) | |

| Table maximum load | kg | 500 | 1200 | 950 | 2000 | |

| T-groove size of work surface (number of grooves x width of grooves x slot spacing) | millimetre | 14x5x 100 | 18x5x125 | 5x18x125 | 22x5x 160 | |

| Pallet exchange time | second | 15 | 16 | 20 | 18 | |

| spindle | Spindle taper | ISO50 | ISO50 | ISO50 | ISO50 | |

| Spindle motor power | kw | 11/15 | 15/18.5 | 15/18.5 | 18.5/22 | |

| Spindle speed | rpm | 20-6000 | 20-6000 | 20-6000 | 20-6000 | |

| Maximum spindle torque (continuous/30min) | Cow rice | 140/191 | 249/307 | 249/307 | 520/619 | |

| Rivet specifications | MAS403 P50T-1 | MAS403 P50T-1 | MAS403 P50T-1 | MAS403 P50T-1 | ||

| precision | X/Y/Z axis positioning accuracy | millimetre | 0.01 | 0.01 | 0.018 | 0.01 |

| X/Y/Z axis repeatability | millimetre | 0.006 | 0.008 | 0.01 | 0.008 | |

| B-axis positioning accuracy | “ | ±4(±15) | ±4(+15) | ±15 | ±4(±15) | |

| B-axis repeatability | “ | ±1(±6) | ±1(±6) | ±4 | ±1(±6) | |

| Tool magazine | Tool magazine capacity | ton | 40/60 | 40/60 | 32/40 | 40/60 |

| Maximum tool diameter | millimetre | Φ125/250 | Φ125/250 | Φ125/250 | Φ125/250 | |

| Maximum tool length | millimetre | 400 | 400 | 300 | 400 | |

| Maximum tool weight | kg | 25 | 25 | 18 | 25 | |

| Tool change time | second | 3.5 | 3.5 | 4.5 | 3.5 | |

| other | The total installed power of the machine tool | kw | 40 | 50 | 45 | 50 |

| Machine Dimensions(L*W*H) | millimetre | 6700x4200x3350 | 7600x4200x3650 | 6500x4100x3450 | 8400×5000×3850 | |

| Machine weight | kg | 16000 | 22000 | 16000 | 26000 | |

Features:

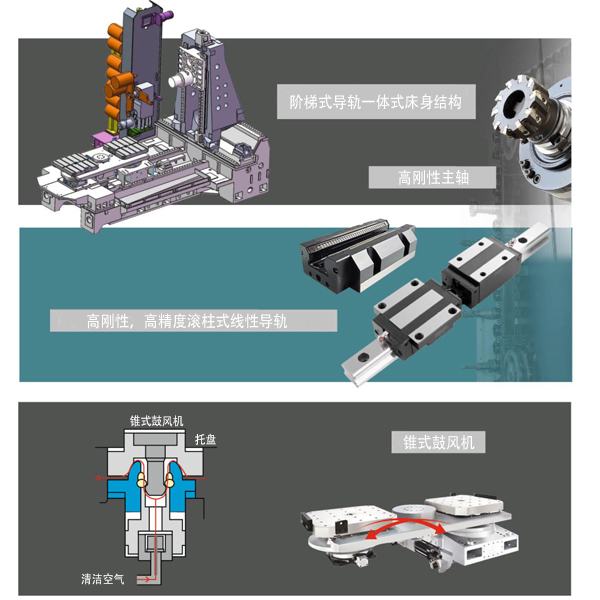

HMC series is a horizontal machining center designed and developed by the company on the basis of absorbing the design concept of advanced machine tools at home and abroad.

This machine adopts T-shaped bed structure design, adopts high rigidity roller linear guide rail, large guide rail span, good overall rigidity of the machine tool, and strong bearing capacity; Equipped with high-precision rotary table, short exchange time, high positioning accuracy of exchange table; The machine can assemble the next part while processing the parts, saving the workpiece clamping time and improving the work efficiency;

This machine is especially suitable for batch processing of large and medium-sized box polyhedral parts. The milling, boring, drilling, tapping and other processes are completed at one time, which greatly improves the processing efficiency.

Product Description :

| serial number | Standard configuration | serial number | Optional |

| 1 | 24 robot tool magazines | 1 | 32 robot chain tool magazines |

| 2 | Spindle air curtain dust prevention system | 2 | 40 robot chain tool magazines |

| 3 | Workpiece cooling system | 3 | Central outlet spindle (with high-pressure cooling) |

| 4 | Equal indexing CNC rotary table | 4 | ZF gearbox transmission |

| 5 | Automatic lubrication system | 5 | Spindle oil cooling |

| 6 | Spiral chip conveyor | 6 | Arbitrary indexing CNC rotary table |

| 7 | Chain type lifting chip conveyor | 7 | Scraper-type lifting chip conveyor |

| 8 | Integral protective shield | 8 | Three-axis encoder control |

| 9 | toolbox | 9 | Tool detection device |

| 10 | Anchor bolts and cushion blocks | 10 | Workpiece inspection device |

| 11 | Door Protector (Protective Door) | ||

| 12 | Hand-held crumb blowing air gun | ||

| 13 | Machine cleaning water gun | ||

| 14 | Simple oil-water separator |

必须是数字

不能为空

E-mail格式不对

手机号格式不对

不能为空

不能为空