Table size: 254x1270mm

Table transverse travel: 810mm

Technical parameters:

| Item/Model | unit | X6325A | ||

| Workbench area | millimetre | 254×1270(10”50”) | ||

| Table transverse travel | millimetre | 810 | ||

| Longitudinal travel of the table | millimetre | 380 | ||

| Vertical travel of the table | millimetre | 400 | ||

| Number and size of T-slots | millimetre | 3×16 | ||

| Telescopic arm travel | millimetre | 470 | ||

| The distance from the spindle end face to the table top | millimetre | 0~400 | ||

| Spindle bore taper | – | Standard: R8 Special Option: ISO 30/ISO40 | ||

| Spindle travel | millimetre | 127 | ||

| Spindle speed | rotate speed | Standard: 16-speed (Shiftgrade) 50HZ: 66-4540 60HZ: 80-5440 | ||

| rotate speed | Special option: stepless variable speed 60-4200 | |||

| Spindle feed | millimetre | Three gears: 0.04 (0.0015")/0.08 (0.003")/0.15 (0.006") mm/rev | ||

| Spindle motor power | kW/hp | 2.25KW/3HP | ||

| The milling head rotates left and right | ° | 90° | ||

| The milling head rotates back and forth | ° | 45° | ||

| Package size | Single-unit packaging | millimetre | 1516x1550x2080 | |

| Two sets of packing | millimetre | 1650x1790x2170 | ||

| Three units in a package | millimetre | 1650x2285x2235 | ||

| Gross weight/unit | kg | 1280 | 1320 | |

Turret milling machines are also known as rocker milling machines

Features:

1. Our milling machine has passed the strict CE certification and has got the CE certificate.

2. Our universal turret milling machine is widely used for machining planes, inclined planes, keyways, keyways, slots and drilling, reaming, boring with its high quality and competitive price.

3. Taiwan original milling head and three-axis Taiwan lead screw ensure that our milling machine performs better than other milling machines. The spindle adopts NSK P4 bearing, which improves the accuracy of the machine and prolongs the service life.

Product Description :

X6323A

1.Y and Z axes are equipped with double 55° dovetail guide rails, which are easy to adjust and maintain.

2. Stiffeners are used on both sides of the column to make the whole machine strong and beautiful.

X6323B

1. The Z-axis adopts a 55° dovetail guide rail, and the Y-axis adopts a rectangular guide rail.

2. Reinforcing ribs are used on both sides of the column to make the whole machine strong and beautiful.

X6325

1. Y, Z axis rectangular guide rail, good rigidity, good stability.

2. The guide rail lining on the saddle is worn out.

X6325B

1. Y-axis rectangular guide, Z-axis 55° dovetail guide. It makes the machine stable and easy to adjust.

2. The saddle guide rail is lined with TF wear-resistant material.

X6325C

1. The milling head is connected by a fixed structure, without ram, so that the cutting strength is large.

2. Y-axis rectangular guide, Z-axis 55° dovetail guide. It makes the machine stable and easy to adjust.

3. The saddle guide rail is lined with TF wear-resistant material.

X6325D

1. Z-axis rectangular guide rail, good rigidity and stability.

2. The saddle guide rail is lined with TF wear-resistant material.

XU6325

1, Y, Z axis rectangular guide rail, good rigidity, good stability.

2. X and Y axis motors 250w. Feeds: 15, 23, 33, 48, 78, 114, 166, 257 (8 types).

X6330A

1. It adopts a fixed structure to connect the milling head, no ram, and has good cutting strength.

2. Z-axis rectangular guide rail, good rigidity and stability.

3. The saddle guide rail is lined with TF wear-resistant material.

X6333

1. Z-axis rectangular guide rail, good rigidity and stability.

2. The saddle guide rail is lined with TF wear-resistant material.

Standard equipment

| pull rod | Handle lubrication | Electrical cabinets |

| Tools & Toolboxes | Work lights | 16-speed milling head |

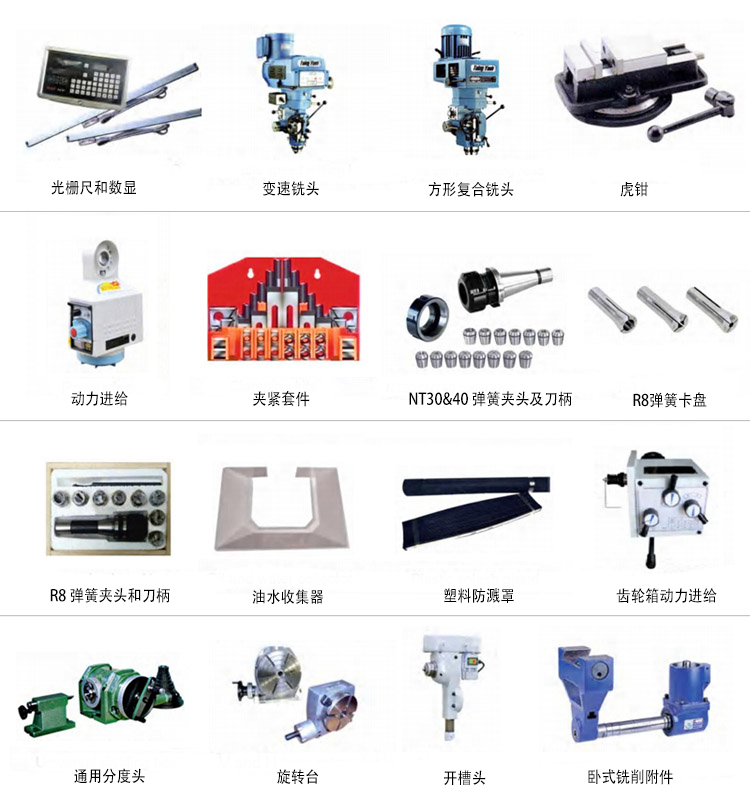

Optional equipment

Plsease input value

Plsease input value