Table size (L*W):

500*600 - 1500*1500mm

Maximum loading weight: 0.5 - 8t

Technical Parameters:

| Model parameters | HLC500 | HLC500S | HLC630 | HLC630S |

| Table size (mm) | 500x6C0 | 500×600 | 630×630 | 630×700 |

| Table maximum load (kg) | 500 | 600 | 1500 | 950 |

| Table indexing (°) | 1°x360/0.001° continuous | 1°x360/0.001° continuous | 1°x360/0.001° continuous | 1°x360/0.001° continuous |

| Table T-groove (number of grooves x wide groove x groove spacing) (mm) | 6x14x80 | 6x14x80 | 5x18x125 | 5x18x125 |

| X/Y/Z Stroke (mm) | 800/600/600 | 800/6201600 | 1000/800/900 | 1050/750/900 |

| Rapid traverse speed (X /Y /Z) m/min | 20/15/20 | 20/15/20 | 20/15/20 | 20/15/20 |

| XYZ cutting speed(mm/min) | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| Spindle centerline to table (mm) | 50-650 | 40-640 | 0-800 | 120-870 |

| Spindle face to table center (mm) | 150-750 |

185~785(BT40)

158-758(BT50) |

200~1100 | 130~1030 |

| Spindle speed (rpm) | 6000 | 6000/8000 | 6000 | 6000 |

| Spindle power (kW) | 11/15 | 11/15 | 15/18.5 | 15/18.5 |

| Shank form | BT50 | BT50 | BT50 | BT5O |

| Pull studs | BT50~45° | BT40-45°BT50~45° | BT50-45° | BT50-45° |

| Tool magazine capacity | 24; 32/40 | 24; 32/40 | 24; 32/40 | 24; 32/40 |

| Tool change time (seconds) | 3.5 | 3.5 | 3.5 | 3.5 |

| Maximum tool weight (kg) | 25 | 25 | 25 | 25 |

| Max. tool diameter (mm) | Φ110 / Φ220 | Φ110 / Φ220 | Φ110 / Φ220 | Φ110 / Φ220 |

| Barometric pressure (MPa) | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Machine weight (kg) | 10800 | 121500 | 13000 | 13500 |

| Machine profile dimensions (L x W x H) mm | 3800x 3000x 3020 | 3800x 2800x 2900 | 4300x 3150x 3800 | 4300x 3150x 3600 |

| HLC800 | HLC1000 | HLC1000S | HLC1250 | HLC1500 |

| 800×800 | 1000×1000 | 1000×1000 | 1250×1250 | 1500×1500 |

| 2000/3000 | 5000 | 1500 | 7000/5000 | 8000 |

| 1°x360/0.001° continuous | 1°x360/0.001° continuous | 1°x360/0.001° continuous | 1°x360/0.001° continuous | 1°x360/0.001° continuous |

| 5x22x160 | 7x22x130 | 7x22x130 | 7x22x150 | 5x28x275 |

| 1200/900/900 | 1800/1400/1400 | 1600/1000/1000 | 1800/1400/1400 | 2500/1500/2000 |

| 20/15/20 | 16/12/16 | 16/12/16 | 16/12/16 | 9/9/9 |

| 1-8000 | 1-~5000 | 1-5000 | 1-5000 | 1-5000 |

| 0-900 | 0~1400 | 120~1120 | 0~1400 | 50~1550 |

| 200~1100 | 250~1650 | 200~1200 | 250~1650 | 610~2610 |

| 6000 | 6000 | 6000 | 6000 | 6000 |

| 15/18.5 | 18.5/22 | 18.5/22 | 18.5/22 | 18.5/22 |

| BT50 | BT50 | BT50 | BT50 | BT50 |

| BT50~45° | BT50~45° | BT50~45° | BT50~45° | BT50~45° |

| 24; 32/40 | 30; 3240 | 30; 3240 | 30; 3240 | 30; 3240 |

| 3.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| 25 | 25 | 25 | 25 | 25 |

| Φ110 / Φ220 | Φ125 / Φ240 | Φ125 / Φ240 | Φ125 / Φ240 | Φ125 / Φ240 |

| 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| 14000 | 26000 | 20000 | 28000 | 34000 |

| 4300x3150x3900 | 7400x 5900x 3820 | 6400x 5500x 3820 | 7400x5900x 3820 | 8200x6900x5000 |

| Model parameters | HLC630SAPC | HLC630APC |

| Table size (mm) | 630×700 | 630×630 |

| Number of workbenches | 2 | 2 |

| Table indexing (°) | 1°x360/0.001° | 1°x360/0.001° |

| Maximum loading weight (kg) | 950×2 | 800×2 |

| Table T-groove (number of grooves x wide groove x groove spacing) (mm) | 5x18x125 | 5x18x125 |

| Max. workpiece size (mm) | Φ960 ×800 | Φ1000 ×900 |

| 3-axis travel (X/Y/Z) (mm) | 1050/750/900 | 1100/800/1100 |

| Three-axis feed speed(m/min) | 20 | 24 |

| Spindle centerline to table (mm) | 0~750 | 50~850 |

| Spindle face to table center (mm) | 130~1030 | 125~1225 |

| Spindle taper | BT50 | BT50 |

| MAXIMUM SPINDLE SPEED (R/MIN) | 6000 | 6000 |

| Spindle motor power(KW) | 15/18.5 | 15/18.5 |

| ATC type, tool capacity | Disc type 30T (optional: chain type 32T/40T) | |

| 3-axis positioning accuracy/repeatability (mm) | 0.018/0.010 | 0.015/0.008 |

| Sharding precision/repeatability | 15/5 | 10/3 |

Features:

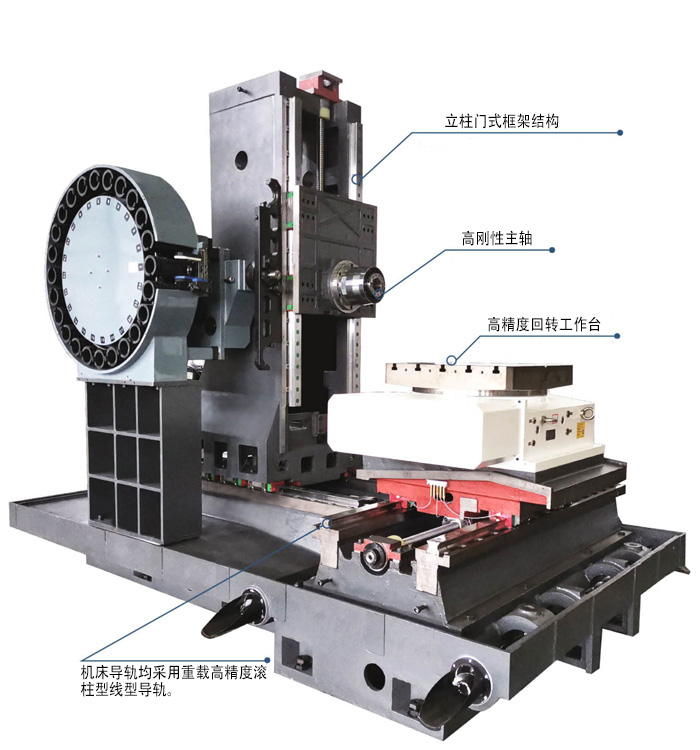

HLC Series The base, column, slide table and headstock of this machine tool are all made of high-quality cast iron HT300. The main foundation adopts a large cross-section dense reinforcement design, and finite element analysis is used to ensure high bending stiffness, high torsional stiffness, high natural frequency, and improved vibration resistance.

Three-axis linear guide for high-speed technical performance. And the accuracy is high. After secondary aging treatment, the internal stress is eliminated. It has the characteristics of good overall rigidity, good vibration absorption and good seismic performance.

It is widely used in the processing of box parts, shell parts and disc parts in military, automobile, mold, machinery manufacturing and other industries. After the parts are clamped once, they can be processed in multiple processes such as milling, boring, drilling, expanding, reaming, tapping, etc., with high precision, high degree of automation, high reliability, high degree of mechatronics, simple operation, and beautiful overall appearance.

Product Description:

HLC series horizontal machining center continues the HC500A, HC630A, HC800A hard way horizontal machine tool structure as a whole, adopts an inverted T-shaped structure, an integrated machine base, an integrated structure with a machine base in front of the bed, and the linear coordinate guide rails are heavy-duty high-precision roller-type linear guides, which have small vibration when the machine tool travels at high speed, no creeping at low speed feed, can carry heavy-duty cutting, and has high-precision stability and dynamic response characteristics.

The machine tool can choose FANUC and Siemens system, and the turntable, tool magazine, spindle, linear guideway, and lead screw are all Taiwanese brands.

| serial number | Standard configuration | serial number | Optional |

| 1 | 24 robot tool magazines | 1 | 32 robot chain tool magazines |

| 2 | Spindle air curtain dust prevention system | 2 | 40 robot chain tool magazines |

| 3 | Workpiece cooling system | 3 | Central outlet spindle (with high-pressure cooling) |

| 4 | Equal indexing CNC rotary table | 4 | ZF gearbox transmission |

| 5 | Automatic lubrication system | 5 | Spindle oil cooling |

| 6 | Spiral chip conveyor | 6 | Arbitrary indexing CNC rotary table |

| 7 | Chain type lifting chip conveyor | 7 | Scraper-type lifting chip conveyor |

| 8 | Integral protective shield | 8 | Three-axis encoder control |

| 9 | toolbox | 9 | Tool detection device |

| 10 | Anchor bolts and cushion blocks | 10 | Workpiece inspection device |

| 11 | Door Protector (Protective Door) | ||

| 12 | Hand-held crumb blowing air gun | ||

| 13 | Machine cleaning water gun | ||

| 14 | Simple oil-water separator |

Plsease input value

Plsease input value