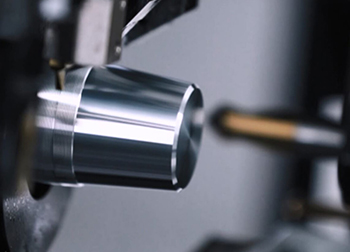

CNC lathes have now been popularized in the market, because of its excellent performance, many manufacturers have purchased products. However, in the process of use, there will be some fault problems, the following is an introduction to how to deal with the high temperature problem of CNC lathe bearing if the temperature of the CNC lathe guide bearing is too high, and its principle. The purpose of the guideway bearing setting is to limit the operation of the generator spindle so that it can only withstand the radial load on the generator spindle within the specified guideway bearing clearance range.

1. The reason for the increase in bearing temperature: the contact point on the surface of the shaft tile is small, the contact surface is insufficient, and it does not meet the requirements of the equipment specifications. The increase of the bearing clearance of the CNC lathe is far greater than the clearance required by the design, which leads to the fact that the lubricating oil is not easy to form an oil wedge when it enters the bearing pad surface, resulting in poor lubrication, resulting in an increase in the temperature of the guide bearing and an increase in the vibration of the unit.

Second, the solution of the temperature rise of the guide bearing of the CNC lathe: when lubricating the surface of the tile, even if the maximum swing point through the spindle, although the matching clearance is the smallest, due to the short distance, good lubrication conditions, less heat generated by friction, and good cooling effect, it will generally not lead to the temperature rise of the bearing, nor will it lead to the burning of the tile.